New Balance 1500 ‘Limited Edition Pack’ | Flimby Trip

To celebrate the release of the Limited Edition Pack along with the 30thAnniversary of the 1500. We travelled north to Flimby, UK to take a closer look inside the ‘made in UK’ factory and to learn more about all that is Cumbrian craftsmanship.

The 1500 is one of the most beloved and coveted New Balance silhouettes in modern sneaker culture. Becoming synonymous with the factory in Flimby since its birth in 1989, the 1500 has been immortalized through an array of collaborative projects. Hanon, Colette, Solebox, Starcow, Crooked Tongues and 24Kilates are the retailers amongst some of the most sought-after pairs that today still sell for exorbitant sums of money.

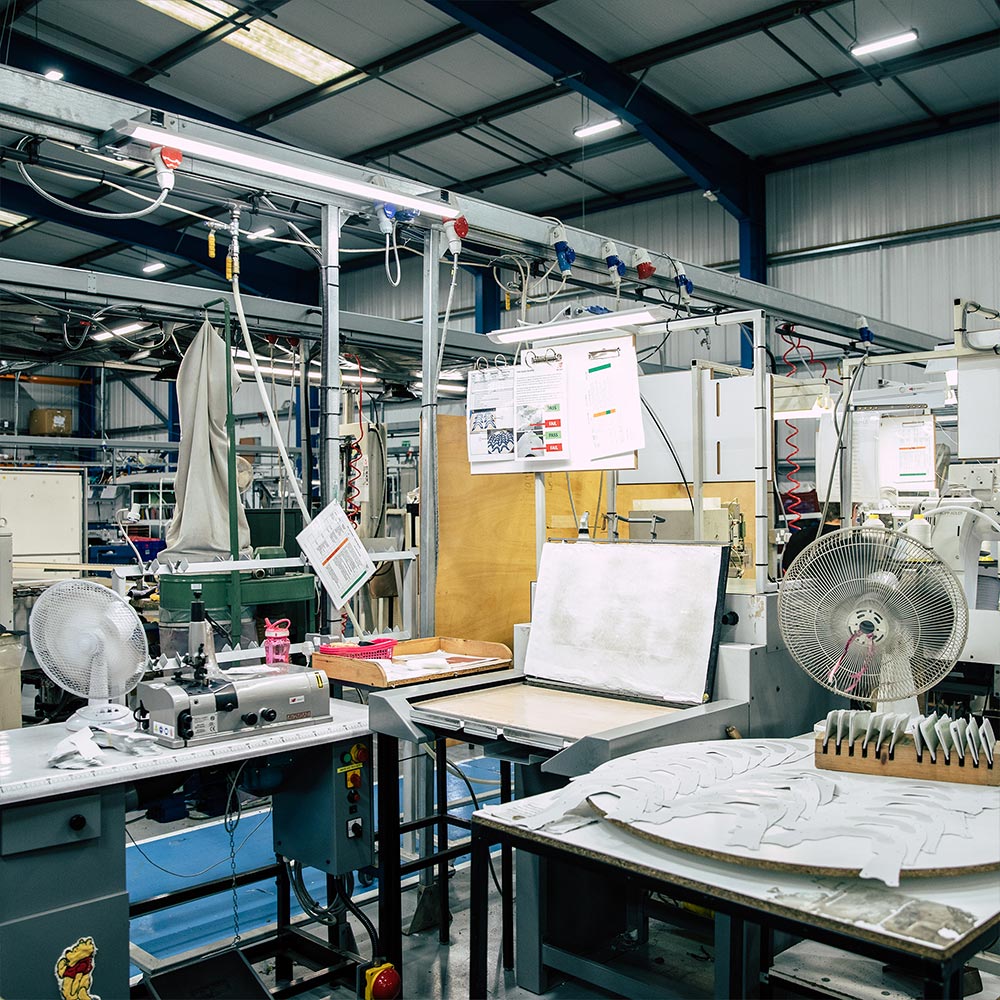

The ‘Made in UK’ line is renowned for its focus on using quality materials with exquisite construction. Engineered meticulously by each of the staff on the production line, every measure is taken to ensure no shoes end up being wasted due to manufacturing errors.

Producing over 28,000 pairs of shoes every week, to the highest level of detail it is an inspirational operation with an overwhelming sense of team work, evident within a small team.

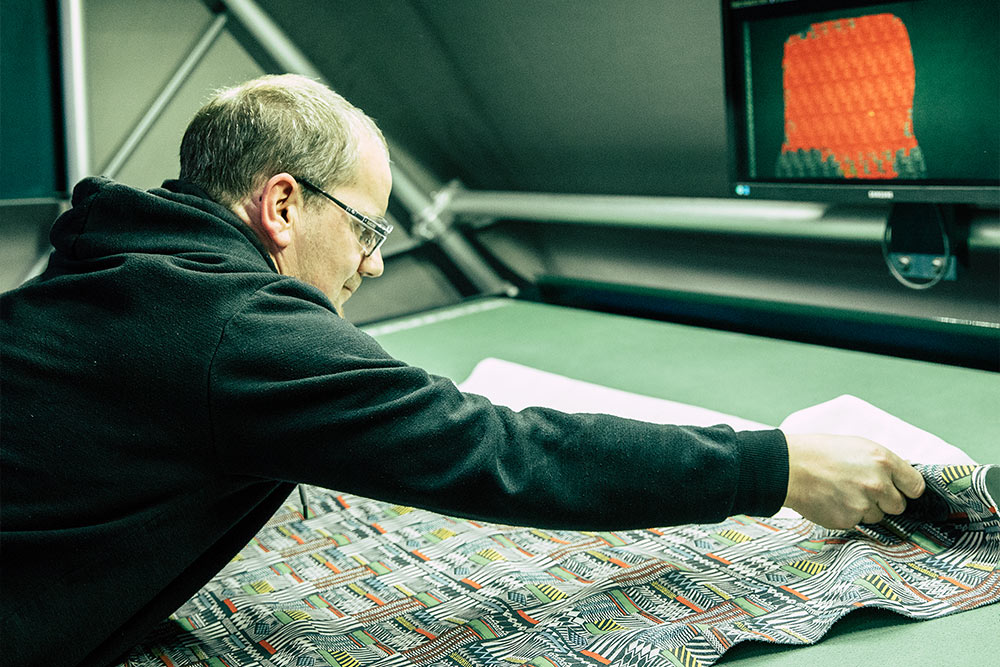

The process starts on shelves stacked with heavy fabrics, utilising the very best quality calf, pig and hide leathers/suedes. The collection of fabrics is vast, and the colour choice is endless. It’s then taken to the cutting templates which are then used to accurately cut out and shape all the many unique pattern pieces that make up each and every style of trainer.

Moving onto the cutting corner, The skill involved in this process isn’t about speed but also accuracy. The fabric can only be cut once therefore the fabric must be used to its full potential with as little waste as possible. Positioning and speed are key skills here, specialist embroidering machinery is used to make light of the workload for the ‘Made in England’ strapline and ‘N’ logo.

The machinery they use is very specialised for each process. The process of sewing the pieces together such as the Tip, Vamp Lining and O’Lay, Saddle, Collar Strap, Foxing and Heel Tabs can look like a grewling process but for the team on deck at the Factory, no job is to difficult.

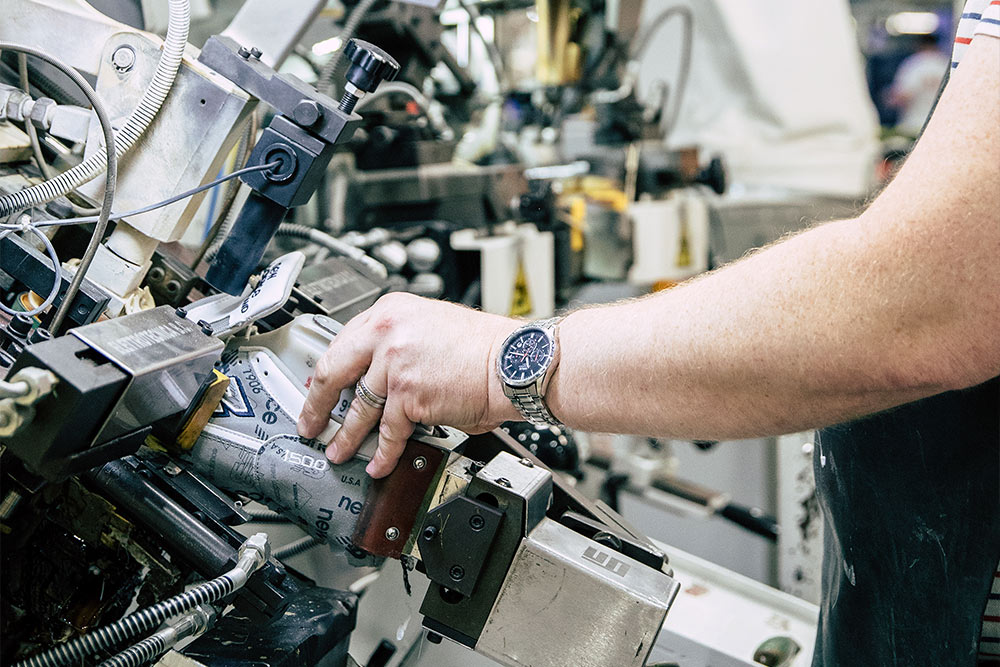

The shoe is then heated in a machine so the glues in the shoe are warmed, ready for shaping in the next process on the other side of the oven. Once removed from the oven there is little time before the shoe starts to cool, so speed, strength and accuracy are key skills at this stage.

The shoe is put into a machine which pulls all the pieces together and glues them to the insole. Then the shoe is quickly taken off the machine and fitted to a ‘shoe last’. Once positioned on the last, the shoe is then passed to the next stage where it is prepared for adhesive to be added to the bottom of the shoe ready for the outsole to be attached.

Final production stages included lacing, boxing and running the shoes through a metal detector, this is to ensure that no tiny bits of metal i.e needles have been lost within the shoes during any part of the manufacturing process.

M15000PRA ‘Limited Edition Pack’ will be launching soon at Footpatrol…!